Aluminum Composite Panels: Benefits, Applications, and Installation

Aluminum composite panels (ACP) have revolutionized the construction industry with their exceptional properties and aesthetic appeal. Composed of two aluminum sheets bonded to a non-aluminum core, ACPs offer a perfect balance of durability, versatility, and affordability.

Benefits of Aluminum Composite Panels:

- Durability: ACPs are highly durable, resistant to harsh weather conditions, and maintain their structural integrity over time. Their aluminum outer layers provide exceptional strength, while the core material offers thermal and impact resistance.

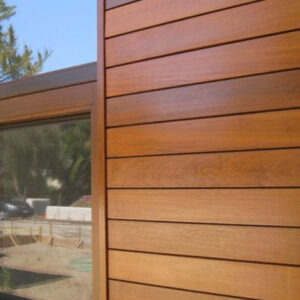

- Versatility: With a wide range of colors, finishes, and textures available, ACPs offer architects and designers immense creative freedom. They can be easily molded, bent, or shaped to achieve innovative designs, making them ideal for both exterior and interior applications. Request to Quote

Applications of Aluminum Composite Panels:

- Building Facades: ACPs are extensively used for building exteriors due to their durability, weather resistance, and design versatility. They provide a sleek, modern look to commercial, residential, and institutional structures.

- Signage and Branding: ACPs are a popular choice for outdoor signage and corporate branding due to their excellent printability, UV resistance, and dimensional stability.

Installation Process of Aluminum Composite Panels:

- Surface Preparation: Ensure the substrate is clean, dry, and structurally sound before installation. Remove any dirt, oil, or loose particles that may hinder proper adhesion.

- Panel Cutting and Fabrication: ACPs can be easily cut and shaped using standard woodworking tools. Precision is crucial to achieve accurate dimensions and smooth edges.

Aluminum Composite Panels, also known as ACM Panels or ACP, is one of the most versatile metal cladding solution available in a variety of textures and colors with both Polyethylene (PE) or fire-retardant (FR) core.

Quick Links:

Technical Details:

| Dimensions | 196 × 62 × 0.02 in |

|---|---|

| Types | Polyethylene Core – PE Core Aluminum Composite Material |

| Thickness | Total Thickness = 3mm / 4mm / 6mm |

| Weight (lbs/sq.ft.) | For 3mm Sheets = 0.93, For 4mm Sheets = 1.12, For 6mm Sheets = 1.50 |

| Fire Performance | Flame Spread: (ASTM E84 – 3mm = 05 / ASTM E84 – 4mm = 00 / ASTM E84 – 6mm = 00) Smoke Developed: (ASTM E84 – 3mm = 15 / ASTM E84 – 4mm = 00 / ASTM E84 – 6mm = 10) ASTM E108 MODIFIED = 4mm and 6mm / Passed Flame Spread Index: (ASTM E84 – 3mm = 5 and for others 0) Other Fire Tests: (ASTM E162 / ASTM E108 / ASTM E119 / UL-94 / UL-879 / NFPA-285 Passed) |

| Production Tolerances (in) | Width: 0.08 / Length:0.16 / Thickness: 0.008-0.012 / Bow: 0.5% / Squareness: 0.2 |

| LEED | Post-Consumer Recycled Content: 3.1% – 7.4% |

| AAMA 2605 | 8.1 Color Uniformity: PASSED / 8.2 Specular Gloss: PASSED / 8.3 Dry Film Hardness: PASSED / 8.4 Film Adhesion: PASSED / 8.5 Impact Resistance: PASSED / 8.6 Abrasion Resistance: PASSED / 8.7 Chemical Resistance: PASSED / 8.8 Corrosion Resistance: PASSED / 8.9 Weathering: PASSED |

| Code Approvals | ICC-ES: (ESR-3704 / ESR-2653) |

Aluminum Composite

What are ACM panels?

Applications

What are aluminum composite panels used for?

Modern Houses

Aluminum Composite materials are available in Solid colors, wood grain finishes, natural steel surfaces, Stone patterns, shimmering colors, metallic coatings, etc. ACM Panels are becoming a popular cladding material in modern architecture in Toronto. Click HERE to see more residential projects. Some of the accentual applications are:

- Main Facade, Porch Siding & Canopies

- Soffit-Works and Fascia Covering

- False ceilings and Interior Partitions

- Column Cladding, Beam Covering

- Modern Pergolas and sunshade Elements

Commercial Buildings

What makes ACM stand out and shine as an architectural element is the quality and availability in almost any textures, finishes and colors. This characteristic is superior to any other natural or artificial medium. Click HERE to see more commercial projects. Some of the very common exterior applications of ACM are:

- Residential Complexes’ Cladding System

- Office Buildings’ Facade Systems

- Commercial Buildings& Storefronts

- Corporate Brands Identity Signage

- Signage with Corporate Colors

- Column Coverings and Beam Cladding

- Unconventional Architectural Shapes

Color Chart

ALPOLIC’s Corporate ID Program opens doors for the brands to find the perfect match for their storefronts cladding and signage.

In NORTEM we help you find the exact color match for your store’s cladding project and brand identity. We supply for many of the well-known brands all across the GTA.

Solid Neutral Colors ACM

This line of ACM comes with 30 Years Finish Warranty

Stone & Wood and Metal Pattern ACM

This line of ACM comes with 20 Years Finish Warranty

Corporate Blue Colors ACM

This line of ACM comes with 20 Years Finish Warranty

Corporate RED Colors ACM

This line of ACM comes with 20 Years Finish Warranty

Finishes

Here is more technical info and detailed catalogs. If you require additional information on all the available finishes, please feel free to contact us now OR leave us a note. Our consultants will contact you very soon.

ALPOLIC® Technical Details

ALPOLIC®/fr (fire-retardant) with a mineral filled core offers the same flatness, rigidity, workability, formability and quality features of standard ALPOLIC®/PE. ALPOLIC®/fr is curvable to a 6" radius.

ALPOLIC® Corporate ID

Reveal your corporate identity in precision matched colors that retain their hue, tone and gloss for years to come. Using materials that can be precisely fabricated into your brand’s instantly recognizable forms.

ALPOLIC® Matte Series

With continuous coil coating using our advanced die coating process, ALPOLIC® materials provide a consistent and smooth matte finish of the most advanced architectural coatings available.

ALPOLIC® Timber Series

ALPOLIC®Timber Series materials are created through a unique image transfer process using state-of-the-art fluoropolymer paint technology.

ALPOLIC® Pigmento

The visible and natural texture of the QUARTZ-ZINC®will remain, but the result is a distinctive shine that offers the deep texture of a natural metal with the wide palette of man-made colors.

installation

In NORTEM we offer comprehensive installation training courses for a broad range of Facade Systems and Fasteners. For further information, please contact us via info@nortem.ca for Industrial, Commercial and Residential trainings.

STEP 1. Measurement

How to Measure ACM Panels

In this Video our installation trainer in NORTEM® will share with you how to perform field measurements before production and fabrication of the ACM panels.

STEP 2. Fabrication

How to Fabricate ACM Panels

In this Video we share with you how to cut the panels with CNC Machines and how to fabricate Aluminum Composite Panels and install the fasteners and extrusions.

STEP 3. Waterproofing

How to Waterproof ACM Panels

In this Video we share with you how to prepare the surface and patch the waterproofing membrane before installation of ACM Panels to protect the Plywood, OSB, and Structure.

STEP 4. Mounting System

How to Install ACM Panels (Part 1)

On this Video we share with you how to install the mounting system before installation of Aluminum Composite Panels to make sure we continue the ACM installation on a straight line.

STEP 5. Final Installation

How to Install ACM Panels (Part 2)

On this Video we share with you how to install ACM Panels on the mounting system and how to adjust and fasten the inter-locking clips and fasteners between ACM Panels, the correct way.

Preparation

Aluminum Composite Panels

Leveling & Mounting

Aluminum Composite Panels

Final Installation

CF Toronto Eaton Center UNIQLO

ARCHITECHTURAL DETAILS

Rain-screen Systems

Sealed systems are designed to create an outward layer of protection against the elements with water-resistant cladding and sealed joints.

Two common examples of sealed systems are referred to as wet seal, a system sealed with caulk and backer rod, or dry seal, a system with gaskets and/or filler strip.

The water-tight barrier depends greatly on the effective application of the joint seal, which should receive regular inspection and maintenance. (from alpolic-americas.com)

Most of the water intrusion is managed in the outer cladding layer, but an interior air water barrier (AWB) is required as a second line of defense.

We’ll compare two common rainscreen systems that manage water intrusion differently. (from alpolic-americas.com)

ALPOLIC®

MITSUBISHI Chemical

ALPOLIC aluminum composite panels retain remarkable tensile strength and deliver superior flatness, rigidity and stability under changing thermal conditions. Since they are lightweight and easy to attach, ALPOLIC‘s panel system has proven itself to be the perfect system for building cladding. ALPOLIC speeds construction times and cuts costs in labour and materials alike. ALPOLIC provides an ACM that offers the rigidity of heavy gauge sheet metal in a lightweight aluminum-faced composite material. ALPOLIC offers superior flatness, vibration dampening, extreme durability and ease of maintenance.

Standard ALPOLIC®/PE with a polyethylene core is available in the following finishes: FEVE (LUMIFLON™) with a wide color and gloss range and PVDF, both fluoropolymer finishes tested to meet AAMA 2605, polyester, and class 1 anodized. Other available ALPOLIC® finishes include Stone and Timber Series and Reflective Finishes (RF).

ALPOLIC ®/fr (fire-retardant) with a mineral filled core offers the same flatness, rigidity, work-ability, form-ability and quality features of standard ALPOLIC®/PE. ALPOLIC®/fr is curvable and bendable to a 6″ radius and can be joined with hot melt adhesive to form complex shapes. In addition, ALPOLIC®/fr is available in the same full palette of bright, clean colors and gloss ranges as standard ALPOLIC ®/PE, as well as Stone Series, Anodized and Natural Metals. Extensive fire performance laboratory testing by independent testing agencies in accordance with requirements set forth by IBC has established ALPOLIC®/fr approval on Type 1, 2, 3, 4 and 5 Construction throughout the United States and Canada when used as a wall cladding material.

5 reviews for Aluminum Composite Panel (ACM Panel)

NORTEM Support Team –

Hello everyone,

Here you can write a review for NORTEM’s Aluminum Composite Panels and Installation Services offered by us. Positive reviews from awesome customers like you would help our new clients to feel confident about choosing us as their next material supplier OR siding contractor. Thank you in advance for taking the time to provide your feedback.

Dimitri –

I have such a great experience with Nortem professional staff. At first I wasn’t happy with Acm panel design but they did not give up and surprised me with alternative layouts until i was satisfied. The installers were so friendly and kind. Installers encountered some difficulties for flat roof water management system! but they solved the problem without hesitation or extra charges. Overall I Highly recommend this amazing company and their staff members.

NORTEM Support Team –

Dear Dimitri!

Thanks for taking the time to share your feedback with us. It means so much when our best customers, like you are, share their experiences with others.

I’m glad we were able to meet your expectations! Your house will end up one of the best Aluminum Composite Panel projects we delivered for a residential building to date! We will share the final photos in our ACM Panels Portfolio page as soon the construction is finished.

Thank you again for your kind words and professional demeanor. We look forward to taking part in more of your modern siding projects in the future.

All the Best, Sam

Marc Collings –

I have worked with Nortem from 2014 and was really satisfied with the delivery time on the products and services. I strongly recommend Nortem and will definitely use this company again for future projects.

NORTEM Support Team –

Dear Marc,

Thank you so much for taking the time to leave us this amazing review. It has been our pleasure to work with unique builders like you, throughout the years. Keep up the great modern construction projects and let us know when your current projects reach to the siding stage. Looking forward to work with you on your next build.

All the Best, Sam

David Michaelov –

Nortem ACM panel is great and even during Covid-19 delivery was much quicker than expected. We have used Nortem product in our new series modern townhouse in 145 Chaplin Crescent, Toronto .The Aluminum composite itself is exceptionally high quality, the costumer service is amazing.

Mike –

I am building a new house in downtown Toronto and I chose Nortem for the exterior facade services in my new home. I’m so pleased with the quality of the ACM. Nortem provided me with a few options and helped me chose the right product. I am also very happy with Nortem’s scheduled installation services as they fulfilled their promises. I would highly recommend Nortem.