FAQs

Frequently Asked Questions

These are the frequently asked questions, please feel free to CONTACT US for more information OR Come and Visit Us in our Showroom.

GENERAL Questions

All You Need to know About Rainscreen Facade Systems

- ACM Panels (Aluminum Composite Panels)

- Aluminum Plate Panels (In total compliance with Fire Codes)

- Cassette Panels (Steel, Corten Steel, and Copper)

- Corrugated Wall Panels

- Concrete Panels (Concrete Tile)

- Window-Wall Systems (Wood / Steel)

- High Pressure Laminate (HPL Phenolic)

- Curtain-wall Systems (New!)

- And more…

Cladding is the process of covering the primary external surfaces of homes or buildings with another material. Including weather resistance, thermal insulation, and visual aesthetics, external cladding is effective in sustaining the longevity and structural integrity of the building.

There are various options of external cladding available; each delivering unique benefits for different applications. Some of the most common types of cladding for construction include:

- Stone Cladding uses thin layers or simulations of stones such as marble, slate, and sandstone. This type of cladding fits over concrete and steel surfaces, adding elements of natural aesthetics.

- Brick Cladding is another type of cladding that creates a more natural and earthy It is one of the most popular types of cladding as it is low-maintenance and adds a degree of sturdiness.

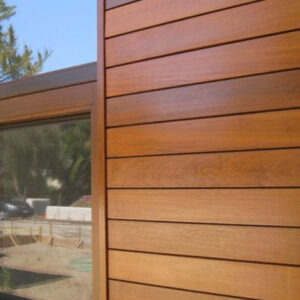

- Wooden Cladding is a classic and one of the most aesthetically pleasing types of cladding materials. However, it is also one of the more expensive types in terms of installation and maintenance costs.

- Fiber Cement Cladding is a sturdier, less expensive and low-maintenance alternative to wooden cladding.

- Concrete Cladding is a form of composite cladding that is installed as concrete panels. It is durable and creates an ultramodern, industrial-esque aesthetics.

- Vinyl or uPVC Cladding is readily used for large-scale residential projects as it delivers value for money and requires close no maintenance. However, it is not as aesthetically pleasing.

- Metal Cladding comes in further different types of metals. Stainless steel and aluminum cladding remains a popular choice. Stainless steel is known to be extremely resistant to environmental factors. Aluminum cladding is most commonly used in the form of aluminum composite panels or ACM panels in Canada. It is slightly costlier but delivers the most value in terms of longevity, maintenance, and functionality.

Excessive moisture retained in walls after heavy rainfalls, storms, floods or snow can quickly become the source of weakened structural integrity and degradation. However, water doesn’t move on its own. It requires gravity, wind, air pressure or capillary action to seep into the walls. The risk of damage is higher for porous material such as bricks and concrete.

Rainscreen systems are installed to prevent water from impinging on the structural integrity of the walls. They are built on the very concept that water needs an external force to move. They are installed over primary surfaces as rain cladding. Here is how a rainscreen system works:

- The outer surface of the rainscreen system, i.e. the cladding material, blocks water’s sideways movement. For example, it deflects water when it rains, allowing it to flow downwards along the cladding layer.

- The second most important aspect of a rainscreen system is the gap between the cladding layer and the primary surface/wall. Any water that seeps through flow downward along the cladding material’s inner surface, which has a water-resistant barrier. At the bottom of the gap between the wall and cladding, there is a drainage hole so the water can escape.

- A gap of at least 3/8th of an inch is crucial for preventing capillary effect.

This is how rainscreen systems keep rainwater away from the wall, preventing it from causing structural damage or mold while sustaining its longevity. Aluminum composite panels of ACPs are effective cladding materials that facilitate the creation of a rainscreen system.

Although a life force, water and excessive moisture retained in walls or foundations of a building can be detrimental for its structural integrity and longevity. It can also be a cause for green or black mold infestation on the exterior or interior sides of the walls.

Rainscreen systems are popular in Canada and were developed to prevent water from seeping through porous construction materials. Cladding materials are installed on top of the primary surface with a ventilation gap to minimize water exposure.

Here are some of the main benefits of a rainscreen system:

- Air circulation prompted by the ventilation gap between the cladding and wall facilitates better regulation of condensation and humidity inside and outside the building.

- The barrier formed by the cladding in a rainscreen system is also an effective aide to insulation. Pressure equalized rainscreen systems are specifically more effective in adding a layer of thermal and acoustic insulation. With better insulation, the rainscreen system can help improve the building’s Indoor Environmental Quality (IEQ).

- Rain cladding allows for improved energy efficiency. It does so by deflecting direct sunlight and heat in the summer and reducing humidity, reducing the load off of the HVAC system. In winters, it prevents cold wind and snow from direct contact with the walls, making temperature maintenance easier.

Rainscreen systems featuring metal cladding, specifically Aluminum Composite Panels, also boast fire preventative qualities. Additionally, NORTEM® tries to optimize modern technologies, challenging traditional typologies, and using as many recycled materials as possible. Furthermore, LEED Certified products are also effective in reducing the overall carbon footprint the building might have.

Canadian climes are known for being extreme. Hot and often humid summers paired with prickling ad blistering winters brings its own set of challenges when it comes to construction. Increased exposure to heat, salt, rain, and snow can be depreciative for buildings and homes.

Architects and contractors must choose materials that can withstand a range of environmental elements including extreme temperatures, humidity, and moisture. The aim is to sustain the building’s structural integrity.

Rainscreen systems, cladding and/or siding materials are used on the exterior of the structure to increase the building’s defense against the environment. There are various siding materials available in Canada.

Brick, vinyl or uPVC (unplasticized Poly Vinyl Chloride), wood, fiber cement, wood fiber composite, and metal are some of the most used siding materials used in Canada. Each material type has unique pros and cons. Architects and contractors make their choice based on the location, the average climate, temperatures, precipitation, etc.

Metal siding, especially Aluminum Composite Panels especially stands out among other materials. Aluminum Plate Panels are an investment but remain the most complimentary to Canadian weather.

- It can withstand extreme weather – hot or cold

- It is effective in deflecting water, protecting brick and wood materials used for constructing the primary structure

- Aluminum is a natural thermal insulator, keeping the indoor space cooler in the summer and warmer in the winter. This can facilitate energy savings

- Aluminum Plate Panels boasts modern aesthetics & give homeowners and project developers more leeway in terms of designing and installation

- And lastly, aluminum cladding is recyclable and durable, often lasting anywhere between 40 and 50 years.

ACM PANEL FAQs

All You Need to know About ACM Panles

Aluminum Composite Material Panel, also known as ACM Panel OR ACP, is an architectural material that has use in both exterior and interior architecture.

ACM Panels, ACPs or Aluminum Composite Material panels are type of material used for cladding buildings’ primary structures or walls for protective and aesthetic purposes. While there are many other materials used for cladding both commercial and residential properties, aluminum composite material remains a more robust, long-lasting, and cost-effective choice.

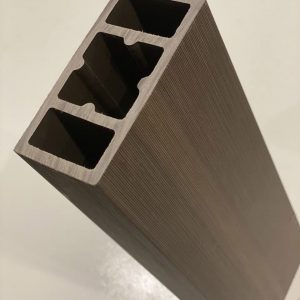

ACM panels are essentially two thin layers of aluminum bonded to a low-density core. The core is a non-aluminum material such as polyethylene (PE) or polyurethane (PU). Or it can be a fire retardant core i.e., a thermoplastic mineral-filled core that offers more compliance to fire codes.

If you were to observe a cross-section of an ACM panel, you would see the sandwiched layers. That is why aluminum composite material panels are also called sandwich panels. Initially, ACM panels were more popularly used in industrial and commercial applications. Their effectiveness as a cladding material, however, has increased their popularity among residential contractors.

Their utility in residential, industrial, and commercial projects is driven by the versatility, durability, and ease of installation. Whether it’s a large storefront, an apartment complex or a modest modern house, ACM panels can be used. They come in a variety of colors and finishes, are lightweight, and easy to customize as per the project’s requirements.

The three-layer aluminum and Polyethylene (PE) or fire-retardant (FR) core is an excellent cladding material effective for both indoor and outdoor applications. Whether residential, industrial, commercial or for signage, ACM Panels suitable if the project requires dimensional stability, cost-effectiveness, and sturdiness from a lightweight cladding material.

ACM panels are favors for contemporary internal and external architectural projects as they have a modern and sleek appearance. They are considered popular as they can deliver:

- Long-lasting durability (40 to 50 years)

- Weather and water resistance

- A wide range and high quality of finishes, textures, and colors

- Lightweight cladding alternatives

- Flexibility

Residential Applications

Some examples of residential applications of ACM panels include:

- Main façades or cladding

- Siding

- Canopy, pergola or sunshade covering

- Fascia coverings

- False ceilings

- Interior partitions

Commercial Applications

Some examples of commercial and industrial applications of ACM panels include:

- Office or residential building cladding or façade systems

- Commercial building and storefront cladding or façade systems

- Signage for corporate buildings or locations to replace heavy substrates

- Constructing unconventional architectural shapes

- False ceilings

- Interior partitions

ACM panels are also readily used to create and install rainscreen systems on both residential and commercial properties. The panels are used to clad the building, leaving a gap between the panels and the wall to allow ventilation.

Furthermore, ACP is also used to construct transient structures. These include booths and temporary stands for trade shows and also as backing material for art displays, etc.

- Residential Complexes’ and Office Buildings’ Cladding

- Commercial Buildings and Corporate Identity Signage

- Storefronts and Signage with Corporate Color Codes

- Column Coverings and Beam Cladding

- Cladding Solutions for Unusual Architectural Shape

- Interior Signage and Corporate Brand Identity Elements

Aluminum Composite Panels (ACM) panels are used to create façades and rainscreen systems and for cladding external structures of homes, buildings, insulation, and signage. They are also often used for internal architectural cladding as well.

With a diverse application range that is not limited to external use, ACPs are widely used in the construction industry. They boast features and benefits that facilitate longevity, cost-effectiveness, and improved durability of building surfaces.

When it comes to the composition of the panels, aluminum composite material is made of a non-metal core bonded to two thin sheets of coil-coated aluminum. Available in a range of colors and finishes, these panels are favored by architects, contractors, and homeowners alike for their durability and aesthetic value.

Even though ACM panels also come in various thicknesses and shapes, they are manufactured the same way. The process begins with coil-coated aluminum sheets and lightweight core materials.

The most standard core material used for ACP construction is Polyethylene (PE) or Polyurethane (PU). While lightweight and effective, this core material is not fire-resistant. An alternative to PE ACP is a panel made with a fire retardant core (FR). This means that the aluminum sheets will be bonded with a thermoplastic mineral-file core, which is more effective when it comes to fire safety compliance.

The exterior surface of ACM panels is then given a metallic finish or coated with PVDF (polyvinylidene fluoride) paint. The paint itself boasts various benefits that further increase the effectiveness of an ACP.

Aluminum composite panels or ACPs have been in use since the 1960s. While initially used primarily for creating and cladding signage, it has been developed further for large-scale applications in residential, industrial, and commercial applications.

In the 1980s, it was the commercial industry that was inspired to use ACM panels for their durability, flexibility, and light weight. Today, ACM panels are considered as effective cladding and façade materials for residential applications.

Despite the benefits ACM panels offer, their flammability remains a prime concern for developers, contractors, and property owners. The source of this concern is the Polyethylene or PE core used in the making of ACM panels.

PE is not just found in the cladding. In fact, it makes up a third of manufactured plastics every day. The type of PE used as a core in ACM panels is high-density polyethylene or HDPE. While the tightly packed HDPE offers rigidity suitable for cladding, it can also have a high combustibility ratio.

However, proper manufacturing processes along with compliance to high industry standards and regulations can prevent hazards.

An alternative to PE core Aluminum Composite Material (ACM) panels are ones where coil-coated aluminum sheets are bonded with a thermoplastic mineral-filled core. This Fire Retardant (FR) core material complies with a more diverse range of diverse codes around the world.

Manufacturers now provide ACM panels reinforced with fire retardant materials. These offer the same flatness, flexibility, aesthetics, quality, and formability one would expect to get from a PE ACM panel.

NORTEM® offers Fire-Retardant ALPOLIC®/FR mineral-filled core ACM panels that can be used numerous applications demanding the features of effecting cladding.

We fabricate and custom-build Aluminum Composite Panels in our facility in Toronto, Canada. We create panels based on the project design and architects’ spec. The only limitation is the dimensions of the raw material which in this case is the dimension of ACM Sheets:

- Panels up to 60” Width x 192” Length

- Panels Thickness: 3mm, 4mm & 6mm (4mm plus core only)

Aluminum cladding is one of the most widely used types of cladding material in commercial applications. More than 60% of industrial and commercial projects feature ACM panels as they are impervious to dust, water, and other environmental factors.

On top of that, it is immune to rust as when exposed to air, an ACM panel created an oxide layer that protects it from moisture. Also, it can last up to 40 years, is lightweight, versatile, and easy to install.

They are more expensive than galvanized steel cladding. Considering the advantages and a wide range of applications, Aluminum Composite panels deliver value exceeding the price. You can consider ACM panels an investment that will last you a long time and require minimal to no maintenance.

ACM Panels can cost between $15 and $30 per panel while flat sheet aluminum cladding starts under $10 per sq. ft.

Keep in mind that prices can increase based on the level of quality. Premium quality ACM panels engineered with a fire-resistant core will be significantly more expensive but just as effective in terms of delivering value.

Aluminum sandwich panels or ACM panels are popular cladding materials used in Canada and Europe. They can be found on modern commercial buildings and storefront along with homes and residential projects.

They are sturdy and flexible, offering homeowners and contractors versatility for contemporary structures. Not unlike any other cladding material, ACM panels also have pros and cons.

Here are some of the main advantages and disadvantages of the cladding material:

Advantages

- Compared to other cladding materials, aluminum composite material offers a long-lasting solution. They can last anywhere between 40 to 50 years without sustaining significant damage.

- ACM panels can help improve a building’s IEQ (indoor environmental quality) as it is a thermal and acoustic insulator. It can help keep the indoors cooler in the summer and prevent hot air from escaping in the winter, facilitating energy savings.

- They are used to create rainscreen systems that can be effective for sustaining longevity and structural integrity of the building’s walls.

- ACPs come in a wide range of sizes, colors, finishes, shapes.

- They are lightweight and easy to transport

- The application process is relatively hassle-free

- The panels require close to no maintenance and are easy to upkeep

- They are more environmentally friendly and a safe alternative as they don’t emit hazardous gases

Disadvantages

- ACM panels can be susceptible to dents and cracks during harsh storms

- Without proper sealant use around edges and joints, the panels may allow water or moisture to seep in can create a capillary effect, damaging the wall or primary structure behind

Aluminum Composite Material panels are also called aluminum sandwich panels or simply sandwich panels. They are called that because if you were to cut a cross-section and look at it from the side, it would appear like a sandwich.

It is made by bonding two thin sheets of aluminum bonded with a lightweight core in the middle. The panels are typically 3 to 7 millimeters thick. The ACM panels are then further laminated with PVDF paint or a metallic finish. You can differentiate the panels from a regular aluminum sheet by looking at a cut edge. The lamination will make it easy to determine whether it a panel. If you can’t find a cut edge, you may have to cut a hole in the panel to check.

Otherwise, the appearance of ACM panels can vary as they are available in various finishes and colors. You can find panels in a sizeable range of solid colors, including neutrals, shades of blue, reds, creams, and more. As for finishes, there are wood, stone, and metallic (copper or zinc) finishes available.

You can choose a type of ACM cladding based on the aesthetics you are aiming to create.

Read our quick guide to Exterior Wall Panels

Check out our Products

Feel free to ask any questions about ACM wall panel systems!